During pyrolysis, carbon from biomass is stored in the form of biochar. Sewage sludge pyrolysis is an excellent alternative way of utilizing sewage sludge. It is used decentrally at the sewage treatment plants. This avoids cost-intensive and environmentally harmful transport.

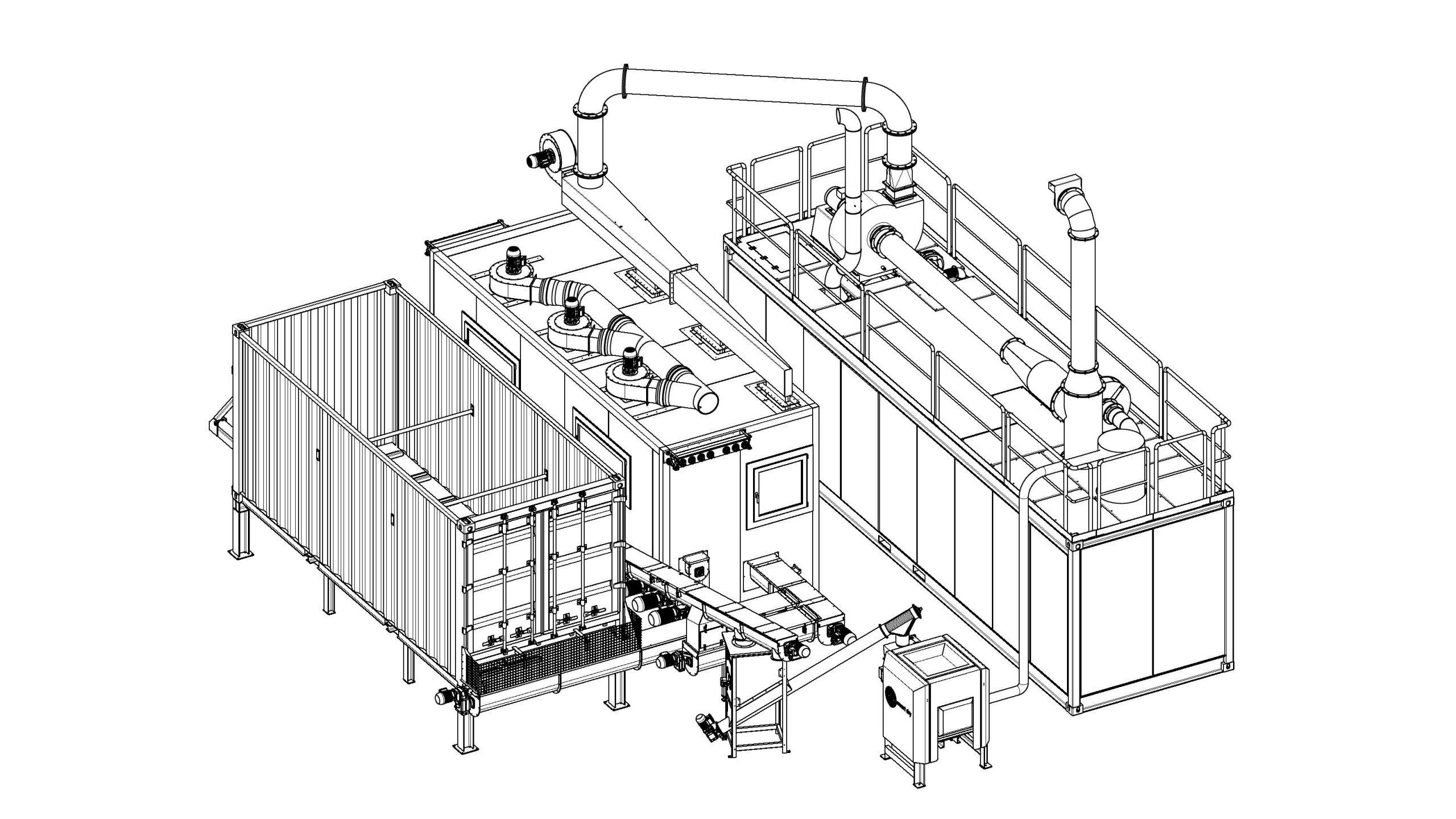

Dewatered sewage sludge is dried independently in the PyroDry® Energie and converted into carbonate (biochar). All chemical components, medical residues, microplastics and PFAS are almost completely destroyed by the high temperatures.

What remains is a carbon-containing pellet which has a wide range of applications as a product. It can be used as activated carbon to keep air and liquids clean. Activated carbon can be used to remove phosphorus and nitrogen from wastewater, as well as pathogenic microorganisms such as bacteria, viruses and parasites. Activated carbon removes organic compounds such as pesticides and herbicides, pharmaceutical residues, industrial chemicals and other organic compounds such as trihalomethanes, which result from the reaction of chlorine and organic compounds, from wastewater.