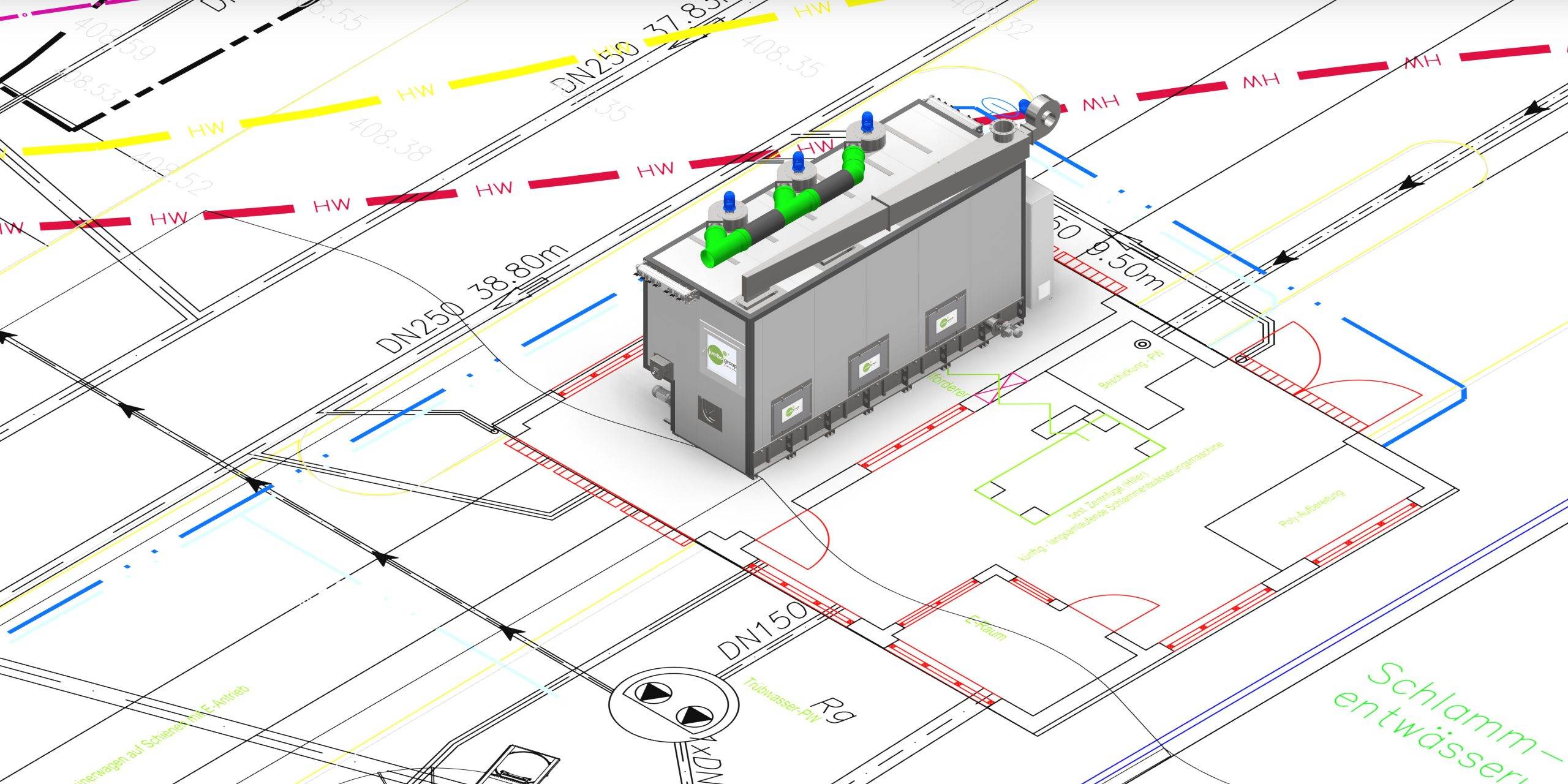

Of course we plan the project together with you.

Made in Germany is not just an advertising slogan for our products, it is lived down to the last detail.

We are very proud of this! High-quality materials, precision in production and the quality of selected suppliers form our maxim. In the end, there is a high-quality, functional product designed for longevity, which thus finds its lasting added value with the customer.

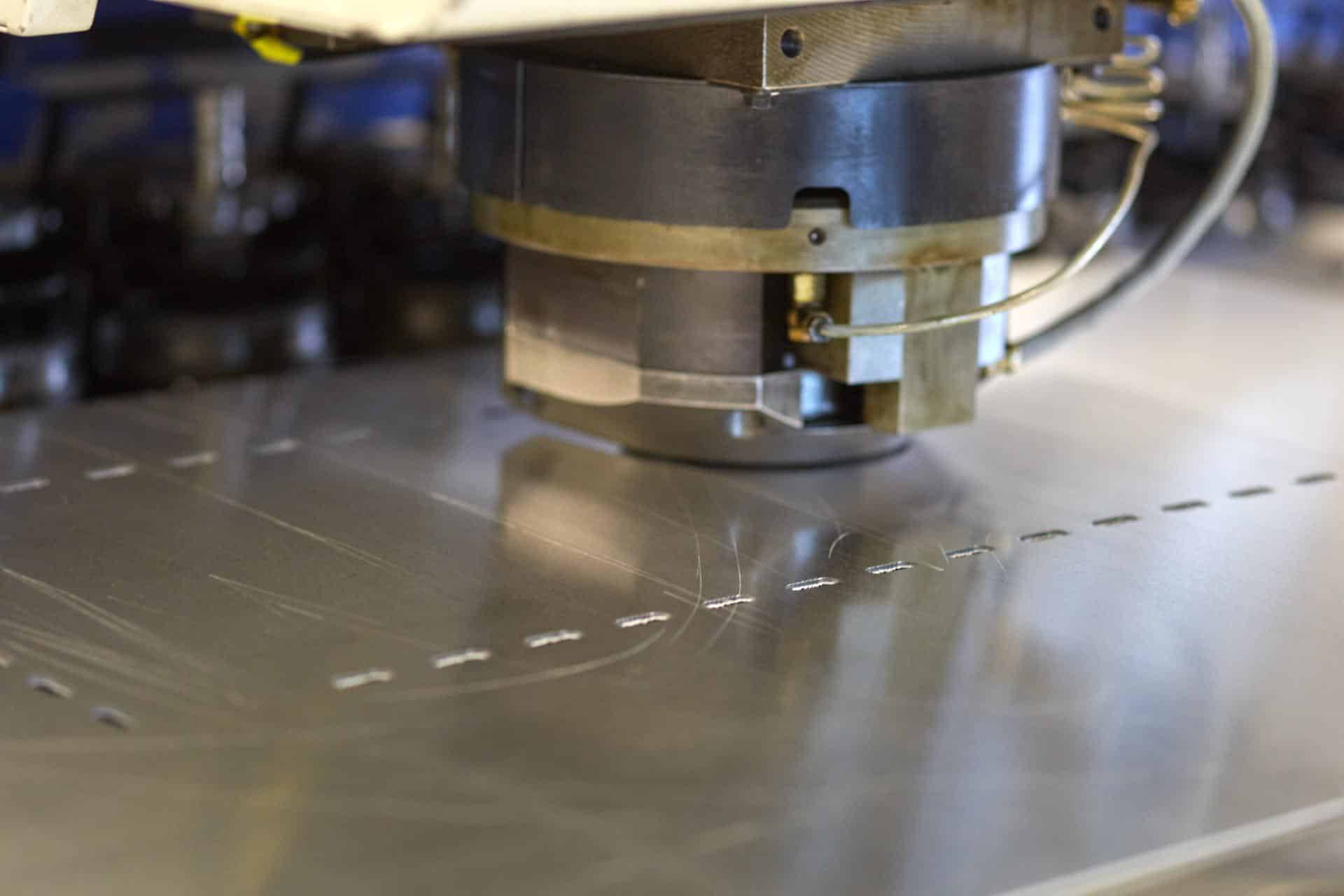

Using the latest laser technology, our raw and structural parts are manufactured from high-quality stainless steel, edged and welded in modules. After production, they are pickled in an immersion bath, thereby achieving maximum protection for the material.

Reliable drive technology from WEG ensures our systems not only proven quality, but also a worldwide service network. Components and drives are designed for permanent 24-hour operation.

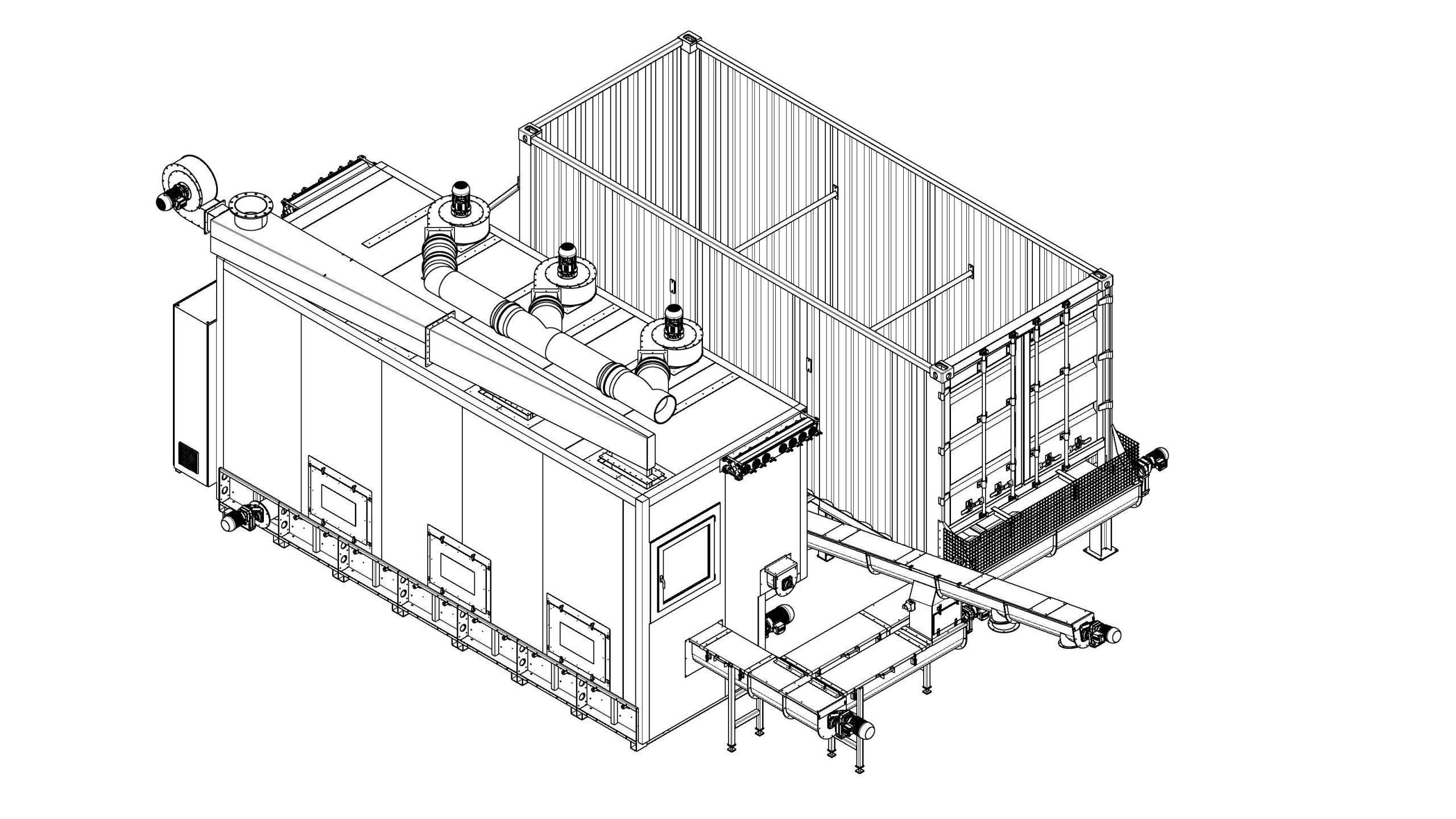

The production takes place according to CAD 3D component drawings. Each component is designed and statically calculated for its application and maximum load. A technically high-quality computer program simulates the real operating conditions.

Electrics, electronics and state-of-the-art control technology from Siemens in accordance with industry standard 4.0 form the platform of our systems for integrated functionality. A system and process visualization, as well as our ARC active remote control ensure a low-personnel continuous operation of our system technology.

We would be happy to advise you without obligation in a personal meeting.