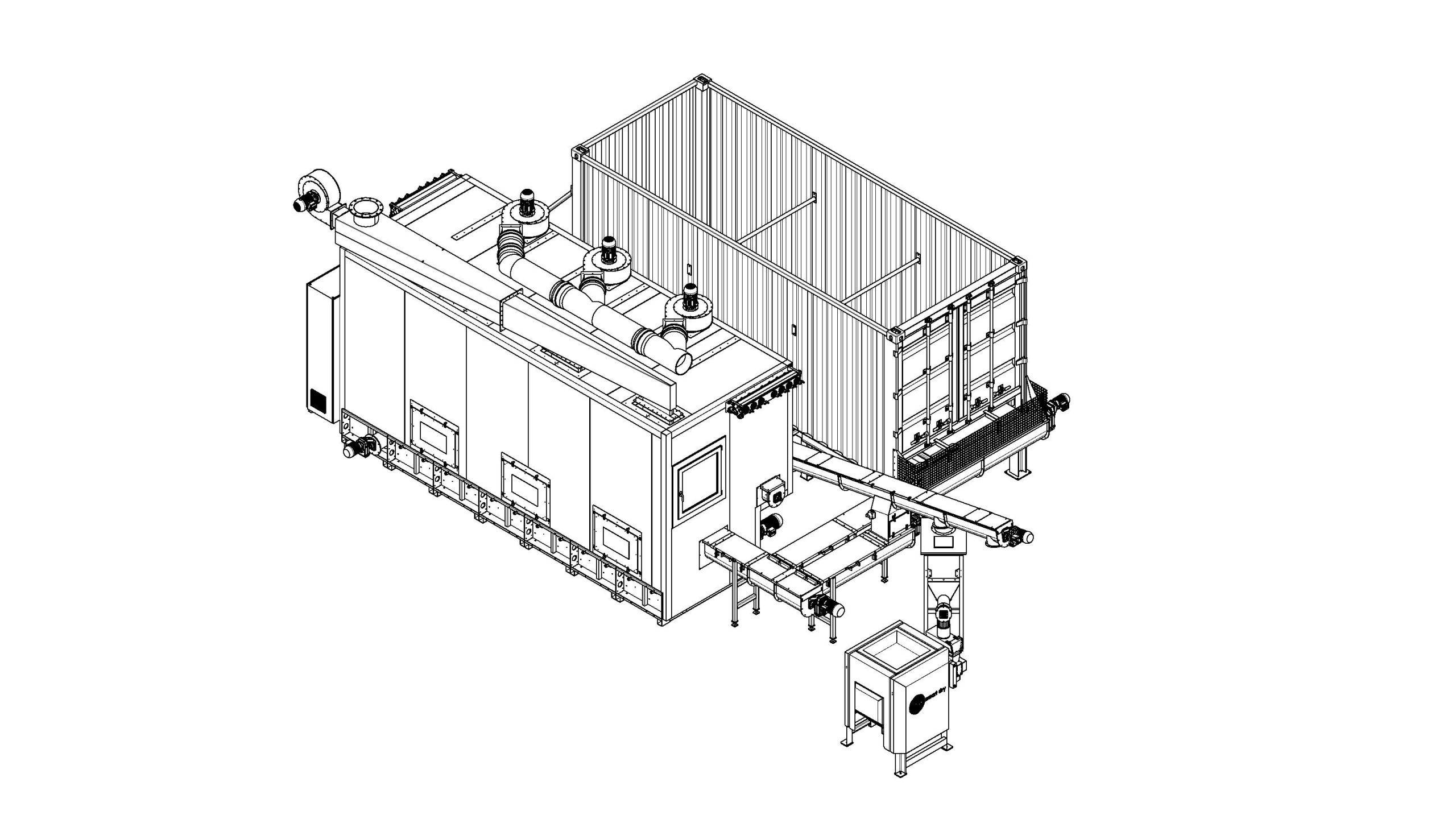

This is possible because our speed rotary dryer creates the ideal physical conditions necessary for the highest possible efficiency. Wet sewage sludge is mixed to a value below the gluing limit via a dry backmix and fed into the drying chamber. Rapidly rotating throwing blades keep the sewage sludge in a cloud of material in the drying chamber.

Schnell rotierende Wurfschaufeln halten den Klärschlamm ständig in einer Materialwolke in der Trocknungskammer. Mit diesem Verfahren wird die maximale Oberfläche für das Produkt geschaffen, In die Materialwolke wird heißes Abgas mit ca. 300°C geblasen. Die hohe Thermokinetik führt dabei zu einer Turbotrocknung. Der Klärschlamm wird binnen weniger Minuten von vormals 75% Feuchtigkeit auf eine Restfeuchte von 10% getrocknet. Der Materialdurchlauf regelt sich vollautomatisch und passt sich auch Schwankungen im Rohmaterial oder in der Energiezufuhr selbständig an.

The exhaust gas from a CHP, a micro gas turbine, pyrolysis, sewage sludge incineration, gas burners or a biomass burner can be used to provide the thermal energy. Several exhaust gas sources can also be used at the same time to ensure the cheapest energy supply on site.

Getrockneter Klärschlamm ist staubig und gesundheitsgefährdent. Dem Trocknungsprozess ist deshalb unmittelbar eine Pelletierung angeschlossen, welche den Klärschlamm zu einem nahezu staubfreien Pellet verpresst. Der pelletierte Klärschlamm ist lagerfähig, kann mit jeder Logistik transportiert werden und für weitere Prozesse verwendet werden.